Two Pews – A Look Behind the Scenes – Part 1 of 2

Because many people have little exposure to woodworking and the manual trades, the process of creating finished furniture from a stack of rough lumber often seems mysterious.

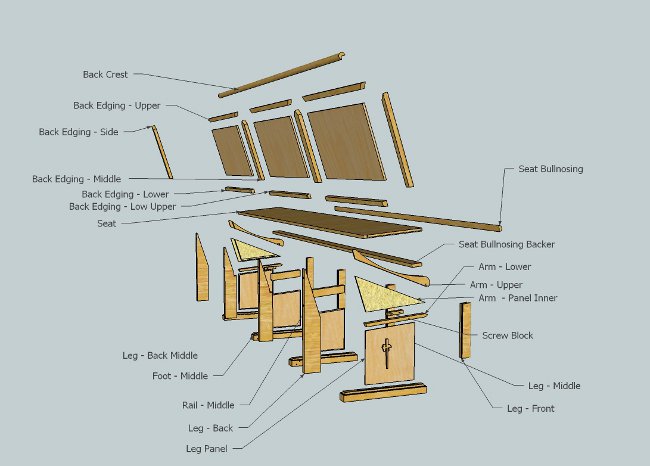

For many custom projects, more than half the work is done not inside the shop, but on the computer (or with pencil and paper for some people). Up front planning minimizes time spent on the shop floor and reduces the chance for error. Before any wood is cut, every part is created and fit together inside the drawing and potential issues are resolved.

Joinery, dimensions, and material selection are accurately depicted here.

With these pews it was quickly apparent that the two biggest issues were the arms and the kneelers (due to the unique parallel arm action).

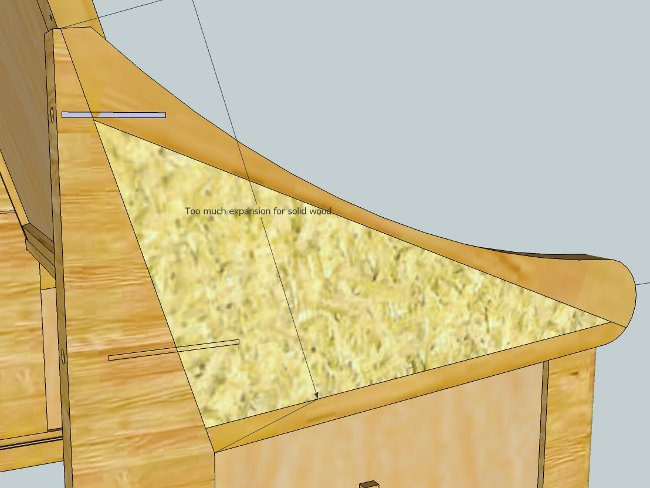

A simple fact that is known to woodworkers is that wood constantly expands and contracts as the humidity changes. The expansion is not equal in all directions though. It is primarily across the grain and almost non-existent along the length.

At the joint, the leg is primarily long grain while the arm would be cross-grain. Both would expand at different rates if they were made entirely of solid wood.

Using a stable panel in the center with solid wood edging all the way around is the ideal solution here. This gives the durability of solid wood to all the corners but stability similar to that of plywood. Those long, narrow rectangles laying across the joint represent screws and let me know what length of screw works best.

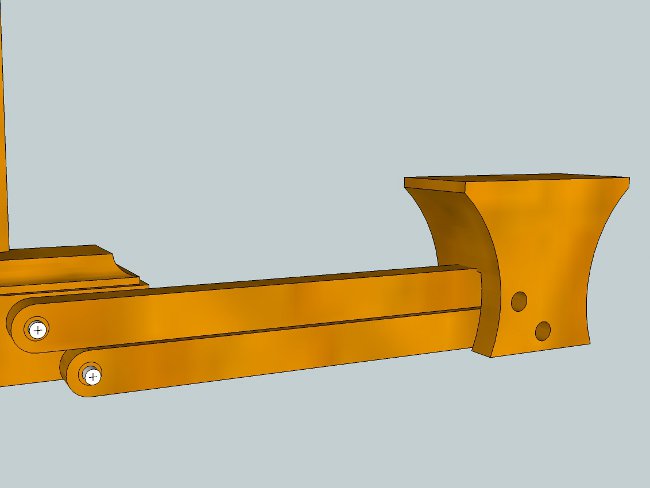

This drawing contains all of important dimensions. Spacing between the arms and the locations of the pins needed to be exact otherwise the kneelers would not function properly.

The kneelers were the most time-consuming aspect of the entire design. Prior to building anything, the entire action was modeled in a computer drawing and the motion tested to ensure proper function. Finally, a full-sized mockup was built.

Building this mockup prevented costly mistakes in the final product. The original 3D model had too short a back and the kneeler hardware wasn’t positioned quite right.

Testing with the mockup made it possible to pick a perfect back height. It also showed us that the kneelers needed to have more than 90 degrees of motion. A slight alteration of the pin placement opened the range of motion to around 110 degrees.

There were many other details that needed resolving during this portion of the design phase but they were much simpler and were easily figured out.