CNC Router – Custom Fabrication

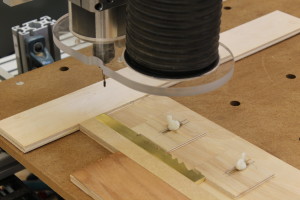

Basic plywood milling is great for odd shapes where conventional methods would require time-consuming templates.

Our most frequent use of the machine is to build specialty components and moldings for our custom furnishings.

Full-sized drawings are done by using the CNC as a large scale plotter. Perfect for making patterns for painting crests.

Many of our projects require customized hardware that cannot be purchased from any suppliers. Here a part for a brass lid stay is milled to shape.

Every CNC operator must do a piece of curved crown molding sooner or later. This was the easy part. At some point handwork was required to cope this into a piece of straight crown.

At Altare Design, we hold the position that the project comes first and the tool is chosen to fit the job – not the other way around. Sometimes a CNC router is the way to go and having one in house allows us to offer a broader range of services.

Thus far we have…

- Drawn full-sized scale patterns for artists to paint by hand.

- Created specialty moldings of all shapes and sizes.

- Produced our own specialty hardware.

- Provided parts for a guitar maker.

- Provided products for an eyewear company.

- Provided parts for an organ builder

- Supplied a furniture-maker with 48 identical plywood pieces.

- Fabricated 150 lineal feet of custom, vented baseboard for use on a gym floor.

- Roughed out blanks destined for hand carving

- Produced dozens of forms for laminations, steam-bending and vacuum forming

Given all of the above, what might be the best reason of all to give us a call? We are not dependent upon the CNC but can utilize many skills, hand tools and machines to perform a wide variety of tasks.

Because it takes more than just CNC to be completely custom shop.

A shop equipped with CNC, a laser engraver and staffed by people skilled with all manner of hand tools and machinery becomes the ultimate CAN-DO resource for customers searching for specialty items.

We can create a finely detailed carving right off the CNC or simply rough out the part and let an artisan finish off by hand.

The undercut details of high relief hand-carved pieces really bring out the three dimensional aspect.

The final step is to complete the piece with hand-rubbed stains and glazes and top-coated with a smooth protective lacquer flawlessly applied through a commercial spray gun.

Couple the CNC with our 3D design services and the possibilities are practically endless. Whether you are looking for a one-time order or a long-term supplier please consider giving us a call.

1-877-517-4568

or email