Handcrafted Furniture – What Does It Mean and What Purpose Does It Serve?

What is the definition of handcrafted? According to the Merriam Webster website, it means “to fashion by handicraft“. Handicraft is further defined as a: “a manual skill” or b: “an occupation requiring skill with the hands” Merriam-Webster Definition Link

The Definitions website defines it as “Made by hand or using the hands, as opposed to by mass production or using machinery.” Definitions Link

A few minutes spent searching the internet and reading blogs and forums will reveal a plethora of different perceptions on the meaning of the term. Some call it a marketing gimmick designed to convince others that a sloppy product is actually worthwhile. Others think it refers to items of quality surpassing that of mass produced goods. Many associate the term with “one of a kind items”.

This sort of work is what comes to the minds of many when they speak of handcrafted furniture.

For clarity the above definitions are listed below.

- to fashion by manual skill

- made by hand as opposed to mass production or by the use of machinery

- poor quality and done without precision

- high quality and not mass produced

- unique and not produced in multiple quantities

Due to the lack of common understanding regarding the term “handcrafted”, there’s a lot of confusion regarding the term “handcrafted furniture”. Most craftsman selling their work are using either the first definition or the last two. Unfortunately, those who do not work with their hands for a living are sometimes disappointed when they discover that most “handcrafted” items are built primarily with power equipment.

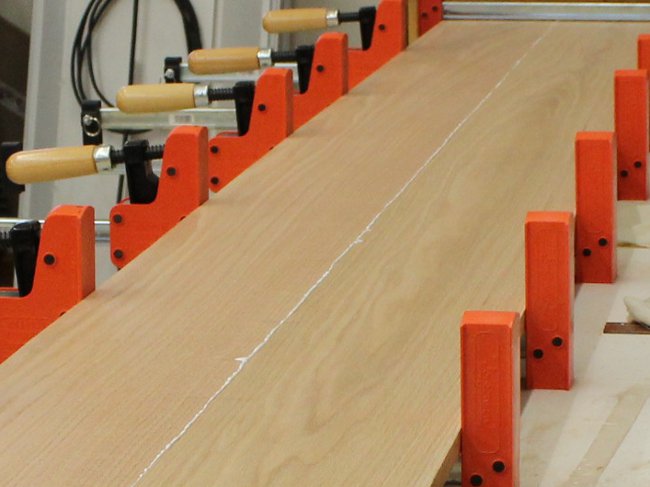

What about this? Handcrafted or not?

Now the third and fourth definitions are problematic. How is it that different people can have the opposite impression of the same thing? This is where it is a good idea to bring up a pair of phrases coined by David Pye – a past professor of the London Royal College of Art.

“the workmanship of risk”

This refers to work done outside of a controlled environment in which the outcome and quality of the end product is not fixed but rather, depends upon the maker’s skill and attentiveness. A brief distraction or a miscalculation is all it takes to alter or ruin the end product. Even the best of craftsmen are at risk of a mistake. Careless or unskilled artisans will produce bad work every time.

Illustration: This pair of spindles didn’t pass inspection. See anything amiss?“the workmanship of certainty”

Products created in a controlled, mass production facility fall under this category. Each item is made to the same specs using an automated process that is nearly 100% certain to turn out perfectly identical items. This is why a car parts manufacturer based overseas in a third world sweatshop can produce millions of components that will all fit perfectly in Fords and Chevys across the USA.

Certainty meets risk – a long row of mass-manufactured clamps is used to join boards for a seat for a custom pew.

For the remainder of this article, when I speak of handmade or handcrafted furnishings, I mean those produced by the “workmanship of risk”.

It is readily apparent that the worst of handmade goods will always be of lesser quality than even poorly manufactured items. The best of manufactured goods will have precision and durability beyond anything handcrafted goods can offer. When people spend a large amount of time and resources developing one product and keep producing that one product, they will inevitably become very good at doing so.

What use then, are handcrafted items if they cost more and cannot achieve the same level of engineering and precision as high-end mass produced goods? Good question, but there are reasons for going handmade. For starters, one should note that the best quality manufactured goods are expensive and are not that much cheaper than quality handcrafted items. But the primary reason is a cultural and aesthetic one.

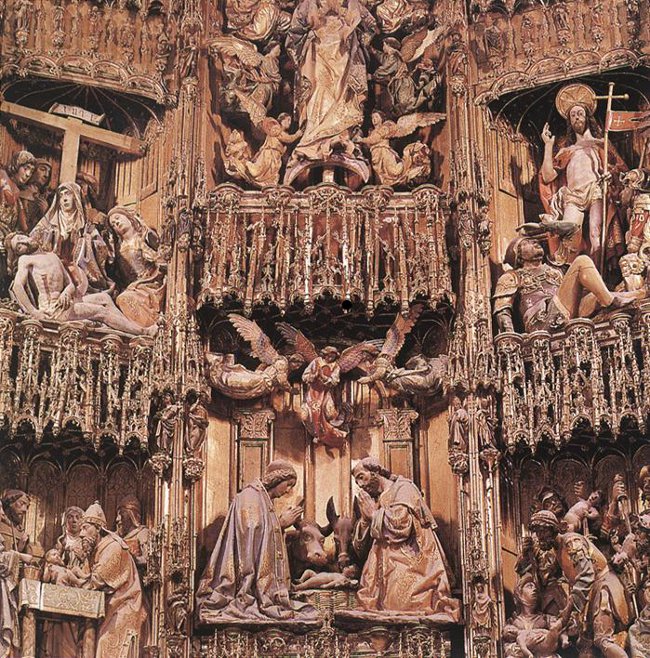

This is a stunning example of how elaborate some of the artwork inside old churches can be.

(Photo: Jim Crail Link to Blog)

The sheer amount of time and development that goes into automating a production line puts severe limitations on the sort of changes that can be made to the product’s design. Car dealers offer options like paint colors and power windows. They don’t give people the option to make their Beetles look like Ferraris.

It would be interesting to find out how much it would cost to setup this altar for mass production. Not going to happen. (Photo: Web Gallery of Art Link to Site)

With a niche market like furniture for Catholic Churches, there’s not enough volume of sales for large companies to create extensive lines of quality products that are ready to roll off the assembly line. It obviously wouldn’t do to manufacture just one line of furniture for every Catholic church. The end result would be cold and sterile. St. Damien’s parish would be identical to St. Philomena’s and the Basilica of the Holy Sepulchre and the Church of the Resurrection would have the same symbolism.

One of two reredos carved in the workshop of Tilman Riemenschneider for St. Jakob Church in Rothenburg, Germany. (Copyright: Micah Cummings Photography Link to Site)

That is why there is still a need for skilled craftsmen that can design and handcraft customized furnishings.